![]() Team manager, Choi Jang-Su. 010-3214-7010

Team manager, Choi Jang-Su. 010-3214-7010

![]() jschoi@anyonetape.com

jschoi@anyonetape.com

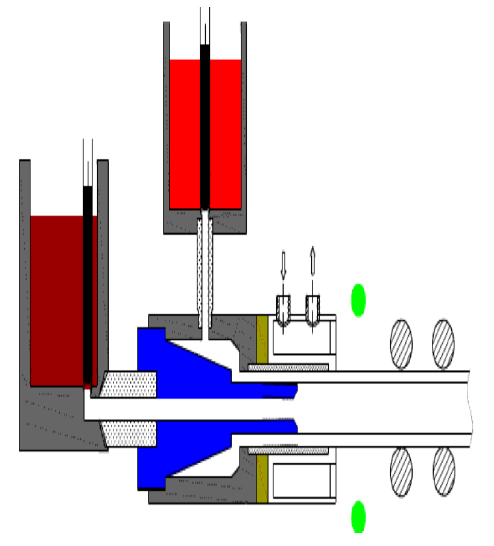

Insert the dissolved copper liquid into the vacuum compound furnace to form

the copper pipe and insert the dissolved aluminum liquid into the copper pipe.

Surface interface fusion is formed as the aluminum and the copper are collaterally melted

which are in the inner walls of the surface of the melted copper pipe at a high temperature.

The copper and aluminum which formed the surface fusion are formed

as a new compound through a chemical reaction and the new

combination(metallurgic combination) is completed, due

to which the surface interface reaction is realized.

The two metal liquids form the stable crystallization zone after being cooled correctly the 2nd

time and the 3rd time after passing the compound molding (this zone is the closed zone filled

with the metal liquid) and any liquid can not enter it.) and when the coagulated bar(sheared

billet) is output after going through the moving processor, the copper aluminum billet is

completed.

| Number | Item name | Diameter | Type | Length | Note. |

|---|---|---|---|---|---|

| 1 | CCA30% | 8.9 | H, A | 3 | |

| 2 | CCA30% | 10 | H, A | 3 | |

| 3 | CCA30% | 11 | H, A | 3 | |

| 4 | CCA30% | 12 | H, A | 3 | |

| 5 | CCA30% | 12.8 | H, A | 3 | |

| 6 | CCA30% | 14 | H, A | 3 | |

| 7 | CCA30% | 16 | H, A | 3 | |

| 8 | CCA25% | 18 | H | 3 | |

| 9 | CCA25% | 20 | H | 3 | |

| 10 | CCA25% | 22 | H | 3 | |

| 11 | CCA25% | 25 | H | 3 |

※ Other non-standard sizes can be supplied after consultation about the sizes.

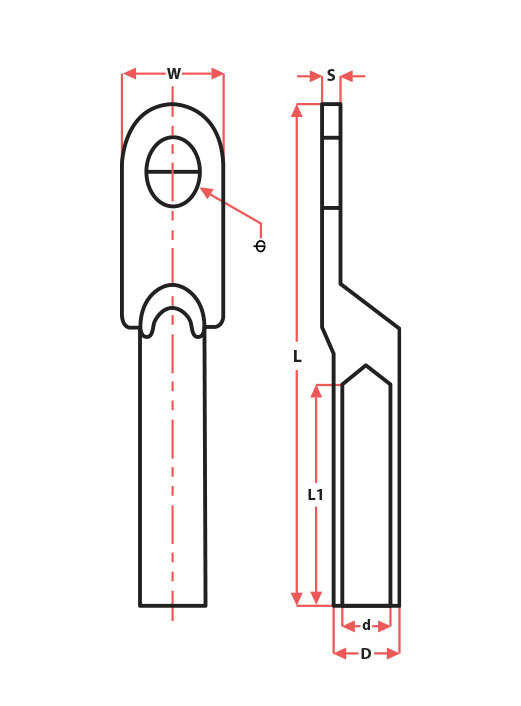

| Model | Sizes of the terminals | ||||||

|---|---|---|---|---|---|---|---|

| φ | D | d | L | L1 | W | S | |

| DTL-16 | 8.4 | 10 | 5.5 | 70 | 32 | 16 | 3 |

| DTL-25 | 8.4 | 12 | 7 | 75 | 34 | 18 | 3.5 |

| DTL-35 | 10.5 | 14 | 8.5 | 85 | 40 | 20 | 3.5 |

| DTL-50 | 10.5 | 16 | 9.5 | 90 | 42 | 23 | 4 |

| DTL-70 | 12.5 | 18 | 12 | 102 | 47 | 26 | 4.5 |

| DTL-95 | 12.5 | 21 | 13 | 112 | 50 | 28 | 5 |

| DTL-120 | 14.5 | 23 | 15 | 120 | 53 | 30 | 5.5 |

| DTL-150 | 14.5 | 25 | 16 | 126 | 58 | 34 | 6 |

| DTL-185 | 16.5 | 27 | 18 | 133 | 60 | 37 | 6.5 |

| DTL-240 | 16.5 | 30 | 20 | 140 | 65 | 40 | 7.5 |

![]() Team manager, Choi Jang-Su. 010-3214-7010

Team manager, Choi Jang-Su. 010-3214-7010

![]() jschoi@anyonetape.com

jschoi@anyonetape.com