![]() Team manager, Choi Jang-Su. 010-3214-7010

Team manager, Choi Jang-Su. 010-3214-7010

![]() jschoi@anyonetape.com

jschoi@anyonetape.com

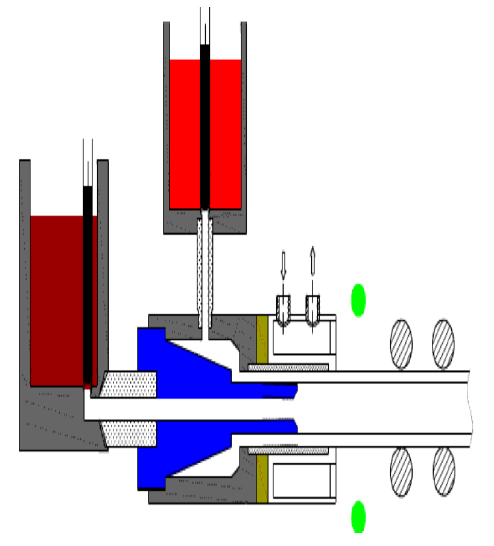

Insert the dissolved copper liquid into the vacuum compound furnace to form

the copper pipe and insert the dissolved aluminum liquid into the copper pipe.

Surface interface fusion is formed as the aluminum and the copper are collaterally melted

which are in the inner walls of the surface of the melted copper pipe at a high temperature.

The copper and aluminum which formed the surface fusion are formed

as a new compound through a chemical reaction and the new

combination(metallurgic combination) is completed, due

to which the surface interface reaction is realized.

The two metal liquids form the stable crystallization zone after being cooled correctly the 2nd

time and the 3rd time after passing the compound molding (this zone is the closed zone filled

with the metal liquid) and any liquid can not enter it.) and when the coagulated bar(sheared

billet) is output after going through the moving processor, the copper aluminum billet is

completed.

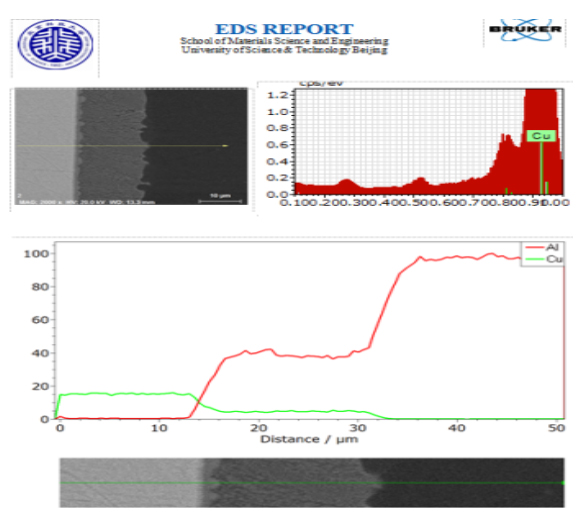

Metallographic photo of the combination status among the atoms in the combined interface.

IMC(Intermetallic Compound/inter-metal compound)

Management 2-0um(GBT standard : 30um or under)

It can be magnified by 200,000 times using the electron microscope. It is the measurement equipment that magnifies the sample by imaging it electronically using the scanning in the various types of electronics or through a bombardment.

It is the probe that analyzes a sort of the energy spectrum and is the equipment that generally equips with the electron microscope and analyzes the characteristics of the electron beam which is dispersed from the non-floating substance and determines the chemical elements and contents.

| Compound volumetric weight | tensile strength | elongation percentage | density | surface combination strength | maximum resistance | volumetric conductivity |

|---|---|---|---|---|---|---|

| (%) | Mpa | (%) | g/㎤ | Mpa | Ω.㎟/m | ≥%IACS |

| 20 | ≥110 | ≥25 | 3.94 | ≥40 | 0.0255 | 67.6 |

| 25 | ≥115 | ≥30 | 4.25 | ≥40 | 0.02498 | 69 |

| 30 | ≥120 | ≥35 | 4.56 | ≥40 | 0.02424 | 71.1 |

| Currents which permits the environmental temperature of 25oC, temperature range of 50K, AC frequency of 60Hx and vertical test. | ||||||||

|---|---|---|---|---|---|---|---|---|

| In case of the parallel, if the width is less than 60mm, the data in the table should be multiplied by 0.95 and if the width is over 60mm, the data in the table should be multiplied by 0.92. | ||||||||

| Thickness/mm | width/mm | copper volumetric ratio 20% | copper volumetric ratio 25% | copper volumetric ratio 30% | Note. | |||

| DC | AC | DC | AC | DC | AC | |||

| 3 | 15 | 193 | 193 | 198 | 198 | 203 | 203 | |

| 20 | 241 | 241 | 247 | 247 | 254 | 254 | ||

| 25 | 292 | 292 | 300 | 300 | 308 | 308 | ||

| 30 | 333 | 333 | 342 | 342 | 351 | 351 | ||

| 40 | 420 | 420 | 431 | 431 | 443 | 443 | ||

| 50 | 498 | 497 | 511 | 510 | 525 | 524 | ||

| 4 | 15 | 219 | 219 | 225 | 225 | 231 | 231 | |

| 20 | 283 | 283 | 291 | 291 | 299 | 299 | ||

| 25 | 342 | 342 | 351 | 351 | 360 | 360 | ||

| 30 | 391 | 391 | 402 | 402 | 413 | 413 | ||

| 40 | 500 | 500 | 514 | 514 | 528 | 528 | ||

| 50 | 597 | 588 | 613 | 604 | 630 | 620 | ||

| 60 | 702 | 689 | 721 | 708 | 740 | 727 | ||

| 70 | 794 | 780 | 815 | 801 | 837 | 823 | ||

| 80 | 881 | 864 | 905 | 887 | 929 | 911 | ||

| 100 | 1093 | 1060 | 1122 | 1089 | 1152 | 1119 | ||

| 5 | 15 | 258 | 258 | 265 | 265 | 272 | 272 | |

| 20 | 325 | 325 | 334 | 334 | 343 | 343 | ||

| 25 | 387 | 387 | 397 | 397 | 408 | 408 | ||

| 30 | 443 | 443 | 455 | 455 | 467 | 467 | ||

| 40 | 569 | 568 | 584 | 583 | 600 | 599 | ||

| 50 | 679 | 669 | 697 | 687 | 716 | 706 | ||

| 60 | 796 | 785 | 818 | 806 | 840 | 828 | ||

| 70 | 913 | 898 | 938 | 922 | 963 | 947 | ||

| 80 | 1027 | 1006 | 1055 | 1034 | 1083 | 1062 | ||

| 100 | 1274 | 1236 | 1308 | 1269 | 1343 | 1304 | ||

| 6 | 15 | 277 | 277 | 284 | 284 | 292 | 292 | |

| 20 | 357 | 357 | 367 | 367 | 377 | 377 | ||

| 25 | 429 | 429 | 441 | 441 | 453 | 453 | ||

| 30 | 490 | 490 | 503 | 503 | 517 | 517 | ||

| 40 | 625 | 618 | 642 | 635 | 659 | 652 | ||

| 50 | 758 | 746 | 778 | 766 | 799 | 787 | ||

| 60 | 885 | 871 | 909 | 894 | 934 | 918 | ||

| 70 | 1020 | 1000 | 1048 | 1027 | 1076 | 1054 | ||

| 80 | 1130 | 1104 | 1161 | 1134 | 1192 | 1164 | ||

| 100 | 1384 | 1344 | 1421 | 1380 | 1459 | 1417 | ||

| 120 | 1622 | 1563 | 1666 | 1605 | 1711 | 1648 | ||

| 150 | 1850 | 1760 | 1900 | 1807 | 1951 | 1856 | ||

| 8 | 15 | 332 | 332 | 341 | 341 | 350 | 350 | |

| 20 | 430 | 430 | 442 | 442 | 454 | 454 | ||

| 25 | 512 | 511 | 526 | 525 | 540 | 539 | ||

| 30 | 594 | 587 | 610 | 603 | 626 | 619 | ||

| 40 | 738 | 728 | 758 | 748 | 778 | 768 | ||

| 50 | 892 | 874 | 916 | 898 | 941 | 922 | ||

| 60 | 1042 | 1018 | 1070 | 1046 | 1099 | 1074 | ||

| 70 | 1195 | 1161 | 1227 | 1192 | 1260 | 1224 | ||

| 80 | 1336 | 1297 | 1372 | 1332 | 1409 | 1368 | ||

| 100 | 1626 | 1564 | 1670 | 1606 | 1715 | 1649 | ||

| 120 | 1896 | 1812 | 1947 | 1861 | 2000 | 1911 | ||

| 150 | 2208 | 2070 | 2268 | 2126 | 2329 | 2183 | ||

| 10 | 15 | 401 | 401 | 412 | 412 | 423 | 423 | |

| 20 | 494 | 493 | 507 | 506 | 521 | 520 | ||

| 25 | 585 | 577 | 601 | 593 | 617 | 609 | ||

| 30 | 674 | 663 | 692 | 681 | 711 | 700 | ||

| 40 | 847 | 831 | 870 | 853 | 893 | 877 | ||

| 50 | 1019 | 994 | 1046 | 1021 | 1074 | 1048 | ||

| 60 | 1186 | 1153 | 1218 | 1184 | 1251 | 1216 | ||

| 70 | 1353 | 1309 | 1390 | 1345 | 1428 | 1381 | ||

| 80 | 1515 | 1458 | 1556 | 1497 | 1598 | 1537 | ||

| 100 | 1838 | 1738 | 1888 | 1785 | 1939 | 1833 | ||

| 120 | 2150 | 2013 | 2208 | 2068 | 2268 | 2124 | ||

| 150 | 2462 | 2283 | 2528 | 2345 | 2596 | 2408 | ||

| 12 | 15 | 448 | 448 | 460 | 460 | 472 | 472 | |

| 20 | 559 | 550 | 574 | 565 | 589 | 581 | ||

| 25 | 666 | 656 | 684 | 673 | 702 | 691 | ||

| 30 | 756 | 743 | 776 | 763 | 797 | 784 | ||

| 40 | 939 | 918 | 964 | 943 | 990 | 968 | ||

| 50 | 1126 | 1095 | 1156 | 1125 | 1187 | 1155 | ||

| 60 | 1310 | 1267 | 1345 | 1301 | 1381 | 1336 | ||

| 70 | 1495 | 1441 | 1535 | 1480 | 1576 | 1520 | ||

| 80 | 1672 | 1594 | 1717 | 1638 | 1763 | 1682 | ||

| 100 | 2025 | 1893 | 2080 | 1944 | 2136 | 1996 | ||

| 120 | 2375 | 2193 | 2439 | 2252 | 2505 | 2313 | ||

width 15~50mm

width 20~150mm

width 30~60mm

width 30~100mm

width 30~120mm

![]() Team manager, Choi Jang-Su. 010-3214-7010

Team manager, Choi Jang-Su. 010-3214-7010

![]() jschoi@anyonetape.com

jschoi@anyonetape.com